A new development by TDK, the magnetic materials pioneer

Compact, High-Sensitivity Magnetic Sensor

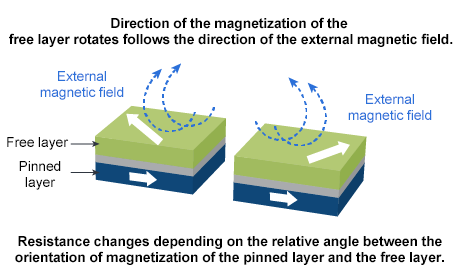

Weak magnetic fields generated by living organisms and small metals contain valuable information. The new MR sensors "Nivio xMR Sensor" and "Migne xMR Sensor" by TDK are revolutionary compact magnetic sensors that can detect extremely weak magnetic fields. What so far was possible only with highly complex equipment installed in some laboratories has now become feasible with much less effort.

-

Enables measurement of weak magnetic fields within the geomagnetic field

Optimal for detecting weak magnetic fields of pT order in geomagnetism

Click here for more details -

Enables measurement of weak magnetic fields within a microscopic area

Optimal for detecting sub-millimeter-order local magnetic fields in geomagnetism

Click here for more details

POINT-01

Compact and ultra-high sensitivity

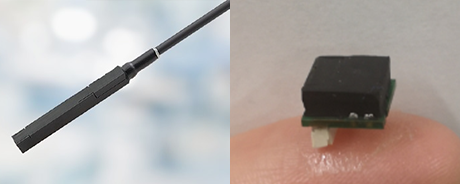

Through its engagement in the manufacture of magnetic heads for hard disk drives (HDD), TDK has continuously played a leading role in the development of xMR (magnetoresistance) element technology. The Nivio MR sensor and Migne MR sensor are TDK’s magnetic sensors that apply highly sophisticated MR element technology to achieve very compact dimensions and high sensitivity. Even magnetic fields much weaker than geomagnetism can be easily detected.

POINT-02

Excellent magnetic resolution and ultra-low noise

The Nivio MR sensor and Migne MR sensor incorporate thin-film devices with a multilayer structure manufactured using a process similar to that used for semiconductor devices. Inherent noise from the sensor element and associated circuitry is kept to an absolute minimum. This has resulted in a drastic signal-to-noise ratio improvement with extremely high magnetic resolution and ultra-low noise characteristics.

POINT-03

Eliminates the need for magnetic shield room facilities

Capable of being applied to a wide variety of applications

The Nivio MR sensor and Migne MR sensor have a wide dynamic range (±45 μT for Nivio and ±200 μT for Migne), allowing easy measurement of magnetic fields anytime and anywhere, without the need for special magnetic shield rooms or other equipment. In addition to general-purpose magnetic sensing and non-invasive testing, the ability to detect weak magnetic fields within the geomagnetic field enable magnetic resolution on the order required for measuring the cardiac magnetic field distribution, magnetocardiography field, and magnetic particle imaging for high-sensitivity identification of tumors and tissues.

Features of the Nivio xMR Sensor

Feature-01

Designed to work at room temperature, eliminating the need for a cooling system

Real-time detection of even weak cardiac magnetic fields

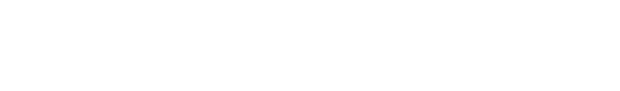

Approaching a noise density of 3pT/√Hz@1Hz which so far was only possible with an expensive and large-scale superconducting quantum interference device (SQUID) magnetometer requiring cryogenic cooling, TDK’s Nivio xMR measures only 12 x 12 x 74 mm and is designed to work at room temperature. This groundbreaking high-sensitivity magnetic sensor is portable, easy to operate, and can be used for measurement at room temperature without the need for a cooling system. It can detect the distribution of weak cardiac magnetic fields at the picoTesla (pT=10-12T) level in real time.

Feature-02

High detection sensitivity even when there are obstructions, such as metal (non-magnetic), water, sand, etc.

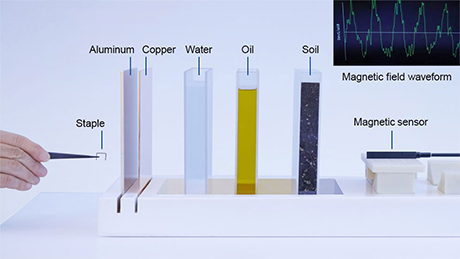

Due to the physical properties of the magnetic field, high-sensitivity measurement is possible even if there are obstacles between the sensor and the measurement target, such as water or oil, non-magnetic metal like copper or aluminum boards, sand or similar. It can also measure weak cardiac magnetic field completely non-invasively while wearing clothes. By utilizing the unique features of weak magnetic field measurement, it is possible to assess the state of an object contained within another object.

Feature-03

Laboratory-class high-precision measurement in a familiar setting

Until now, superconducting quantum interference device (SQUID) magnetometer with cryogenic cooling in laboratories was required. With a high dynamic range of ±45uT, the Nivio xMR sensor does not require a cooling system, making it now possible to perform the same high-precision measurement in smaller medical facilities, enabling more patients to be accurately monitored. Furthermore, it is not only humans for whom important information is contained in weak magnetic field fluctuations, but also objects and natural environments. Depending on the application, there is a potential to trigger problem-solving innovations in various fields.

Press Releases

- Jun. 7, 2016

- March 13, 2019

- September 6, 2021

Examples of application

- J-STAGE

- IOP SCIENCE

- AIP

Related Articles

Features of the Migne xMR Sensor

Feature-01

A revolutionary solution for measuring weak magnetic fields in microscopic areas

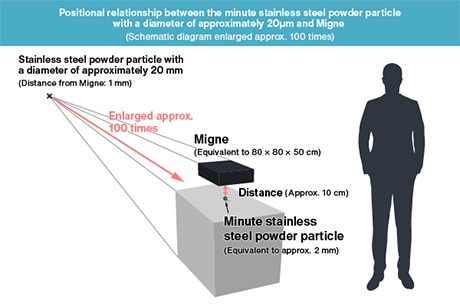

The Migne xMR sensor is a magnetic sensor that enables the measurement of weak magnetic fields in a microscopic level of less than several tens of micrometers. The left figure shows a schematic diagram magnified about 100 times (sample: extremely small stainless steel powder, 20µm in diameter, 1mm distance to sensor) to give a sense of its amazing performance. 100 times magnification is equivalent to detecting the weak magnetic field of a 2mm diameter stainless steel piece at a distance of 10cm from the sensor. Therefore, the sensor shows excellent performance not only in food, pharmaceutical, and chemical industry products, but also in the inspection of magnetic metallic particles in electrode materials and separators of lithium-ion batteries and fuel cells.

Feature-02

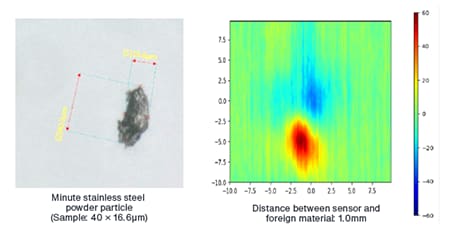

Superior sensitivity and high signal-to-noise ratio enable detection of even the smallest stainless steel particles

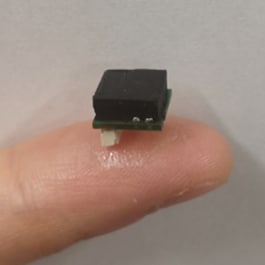

Food, pharmaceutical, and chemical manufacturers frequently use X-ray inspection machines to detect foreign microscopic particles that may be contaminated during the manufacturing process. However, the detection sensitivity of X-rays is limited to several hundred micrometers. Therefore, for tiny metallic particles of 100 μm or less, various types of metal particle detectors are also used. The Migne xMR sensor is a leading edge magnetic sensor capable of detecting extremely small magnetic metallic foreign particles (iron, rust, stainless steel, etc.) of less than several tens of micrometers in size. The high sensitivity and high resolution of the xMR sensor is achieved in an ultra-compact size of 8 x 8 x 5 mm.

Feature-03

Magnetic sensors suitable for magnetized metal detectors

The Migne xMR sensor is a leading edge magnetic sensor that enables the detection of ultra-tiny stainless steel particles, which has been extremely difficult in the past. Various magnetic sensors are used for magnetized metal detectors that magnetize iron and stainless steel particles by using powerful magnets and then detecting them. On the other hand, TDK's Migne xMR sensors are compact, thin, and ultra-sensitive magnetic sensors which are based on advanced spintronics technologies through TDK’s engagement in the manufacture of magnetic heads for hard disk drives (HDD).

Related Articles

-

Nivio xMR Sensor

●Highly sensitive magnetic sensor that can be used at room temperature without the need for magnetic shielding

●Size:12 x 12 x 74 mm

Click here for more details -

Migne xMR Sensor

●Ultra-compact, high-sensitivity magnetic sensor designed to detect extremely weak magnetic fields

●Size:8 x 8 x 5 mm

Click here for more details